This article is produced in partnership with KuriosIT

Faced with global competition, the economic uncertainty brought by recent tariffs, and increasing productivity demands, digital transformation and artificial intelligence (AI) have become an absolute necessity. Yet, for many manufacturing companies, the path is full of obstacles: where to start when data is non-existent, only on paper, fragmented, inaccessible, or locked in silos? How can it be transformed into a true driver of growth?

In this two-part series, we first introduce the foundations of the smart factory and AI in the manufacturing sector. The second article, coming soon, will focus on concrete use cases, illustrating the benefits of having available, reliable, and well-structured data.

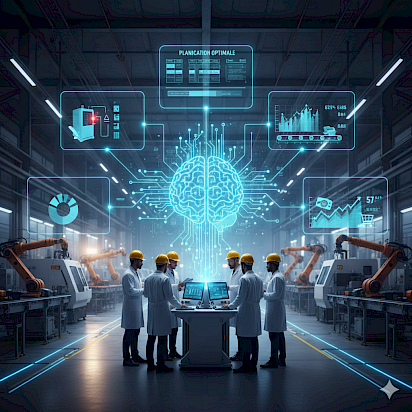

The Smart Factory: The Foundation of Artificial Intelligence

In a modern factory, data comes from multiple sources: ERP, CMMS, MES, IoT sensors, PLCs, machines, tools, and more. Each of these sources holds part of the operational story, but unfortunately, they are often siloed, making a global analysis difficult.

AI, for its part, must be fuelled by data to function properly and unleash its full potential. Consequently, before reaping the concrete benefits of this technology, it is necessary to ensure that the existing IT systems are relatively robust.

This is precisely where the concept of the smart factory comes into play. A smart factory is an automated and connected production environment where machines, sensors, and IT systems collaborate in real time to optimize performance, quality, and operational flexibility. At a high level, the smart factory allows companies to move from a fragmented vision to integrated operational intelligence, with systems that finally “talk” to one another. It aims to achieve this objective in three ways:

- Centralizing real-time data;

- Putting that data into context (e.g., linking a machine alarm to a production step or a maintenance intervention);

- Archiving data in a structured manner.

Concretely, to build solid foundations, it is recommended to implement the following principles progressively and according to priorities:

-

Shop-floor data collection through automated acquisition by PLCs, sensors, vision systems, etc. Data must be collected directly at the source to avoid input errors and information loss;

-

Real-time analysis to detect deviations, adjust production parameters, and trigger alerts. It is therefore important to eliminate siloed systems and replace Excel spreadsheets, which limit the large-scale use of data;

-

Collection and standardization of business data using specialized systems such as ERP (Enterprise Resource Planning), CMMS (Computerized Maintenance Management System), and MES (Manufacturing Execution System);

-

Consistent data historization, which is essential for traceability, continuous improvement, and quality.

These foundations pave the way for more advanced solutions, notably those based on AI. It is not necessary to implement everything at once, but it is crucial not to build on weak foundations.

Artificial Intelligence: Data as Raw Material

The rapid rise of artificial intelligence is largely due to advances in machine learning, a technique that allows systems to learn directly from data. That is why data is not just a technical element; it is a central pillar of any AI initiative.

To leverage data effectively, here are a few guiding principles to keep in mind:

-

Data quality is paramount. This is a non-negotiable principle: if your data is poor, incomplete, or inaccurate, the AI’s conclusions will be as well. The trust you can place in an intelligent system depends directly on the reliability of its information sources. Implementing a smart-factory solution helps improve this reliability at the source by automating data collection and reducing manual handling.

-

Start small, in a targeted and iterative way. A full and costly overhaul of your IT systems is not required to get started. The winning approach is to start small and build progressively. Each AI solution is designed for a specific task and therefore uses its own data set. For example, a quotation-generation tool may rely on historical quotations and technical drawings, while a production-planning solution may use current orders, deadlines, and equipment setup times. Over time, nothing prevents these specific solutions from feeding each other, thereby creating a richer and more efficient AI ecosystem.

-

Adapt data collection to the actual need. Some AI projects require a large volume and variety of data, while others are more targeted. Forecasting future product demand, for example, may require data from various sources such as historical orders, transportation distances, and economic indicators. In contrast, early detection of anomalies in equipment may rely on a narrower and more specific data stream (e.g., vibrations, sound emissions) from real-time sensors. It is therefore important to ask: what data matters most for my AI project?

-

Use data to measure your progress. A frequently underestimated aspect of data is its ability to establish a baseline. Beyond feeding an algorithm, it is essential for evaluating your current performance and quantifying your gains. For instance, measuring a parts-rejection rate before and after implementing an AI-driven quality-control system is a perfect way to concretely demonstrate the impact of the solution.

A Winning Combination

Now that we have reviewed the concepts of the smart factory, the importance of structuring data at the source, and the role of AI in harnessing it, how can this combination translate into tangible benefits for manufacturing SMEs? Here are a few concrete examples:

- Predict equipment failures before they occur to prevent costly, unplanned downtime;

- Plan and schedule operations optimally, reducing idle time and maximizing productivity;

- Synthesize data from disparate systems (e.g., ERP, CRM) to achieve a coherent and actionable overview;

- Improve quality control with real-time visual defect detection;

- Optimize commercial strategies with recommendations based on dynamic data analysis (e.g., smart pricing).

In conclusion, the smart factory and AI form a complementary duo: one enables real-time data capture and structuring, while the other transforms this raw material into strategic intelligence. Together, they generate efficiency and productivity gains that will help you stand out from the competition.

Stay tuned! A second blog article will follow shortly, focusing on concrete use cases that demonstrate the added value of combining the smart factory with artificial intelligence.

Absolument, plusieurs programmes d'aide et crédits d'impôt facilitent également l'adoption de ces technologies avancées par les PME, rendant l'IA plus accessible que jamais. Consulter les programmes de subventions ici